© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

The most important thing in humans life has always been water. Water in any form is a sign of life. In the old days, water was consumed without any treatment system directly. However; as we advanced in the field of science and technology, our environment was polluted heavily, and now we can't use water without processing through the purification system. There are many companies in the world, which are manufacturing different type of water treatment system. One of those companies is a China-based company HENGYU machinery. This company is manufacturing different types of machinery, including water treatment machinery from the past 20 years.

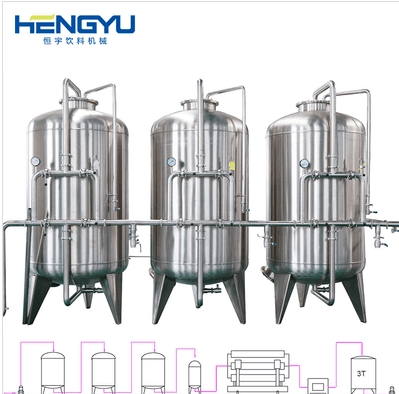

The company produces a different type of equipment as per customer's requirement for water purification. A purification system consists of different types of equipment like water tank, ozone generator, precision filter, UV sterilizer, reverse osmosis, hollow fibre filter, sodium ion exchanger, active carbon filter, and silica sand filter. The water treatment system produced by the company has a treatment capacity of 0.5 to 50 ton per hour. The treatment system can effectively get rid of the muddy organic matter, oxide minerals, manganese, and iron. Along with these harmful minerals, microorganism, chloride, heavy metal ions, solenoid, and filter suspended substances are also removed from the water. The purification system also helps in reducing the hardness of water so the purification system of the water can meet the standard of quality drinking water.

When we take any water treatment system, we'll also have to take the required details of a standards procedure of controlling the quality control. A water purification system consists of multiple parts. Preliminary treatment is the initial part of the purification system through which the water goes through the main treatment system. The purpose of this preliminary system is to remove any material in the water, which can cause further problems in the main treatment system. For quality control of this preliminary system, we need to check different parts of the system. First of all, the flow measurement should be frequently checked to adjust the chemical feed rate, to calculate the detention timing, and to monitor the amount of water in the system. The preliminary system should also be controlled to check other required characteristics like ph factor, alkalinity, temperature, bacteria control, and turbidity. Further; the system is also controlled, so the temperature is checked in such a way that cold water and warm water is not mixed.

An important part of the water treatment system is aeration. It is a process of bringing air and water in close contact. The aeration procedure removes the dissolved gases and metals from the water. It also helps in removal of organic chemicals. The aeration procedure is completed by sweeping action. The sweeping action is caused by turbulence of air and water mixing together. There are different chemicals which are affected by aeration procedure such as volatile organic chemicals. Volatile organic chemicals include benzene, which is found mostly in the dry cleaning procedure. So, if your aeration process is not checked frequently, these harmful gases can be mixed with drinking water that can affect the quality of the water treatment system.