© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

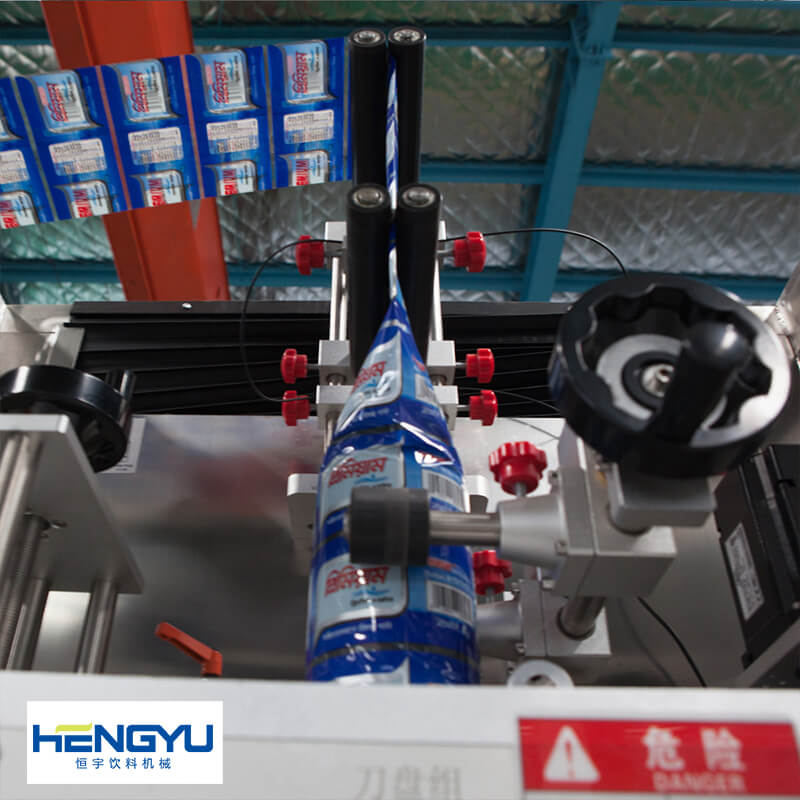

Double Head Shrink Sleeve Labeling Machine

Introduction

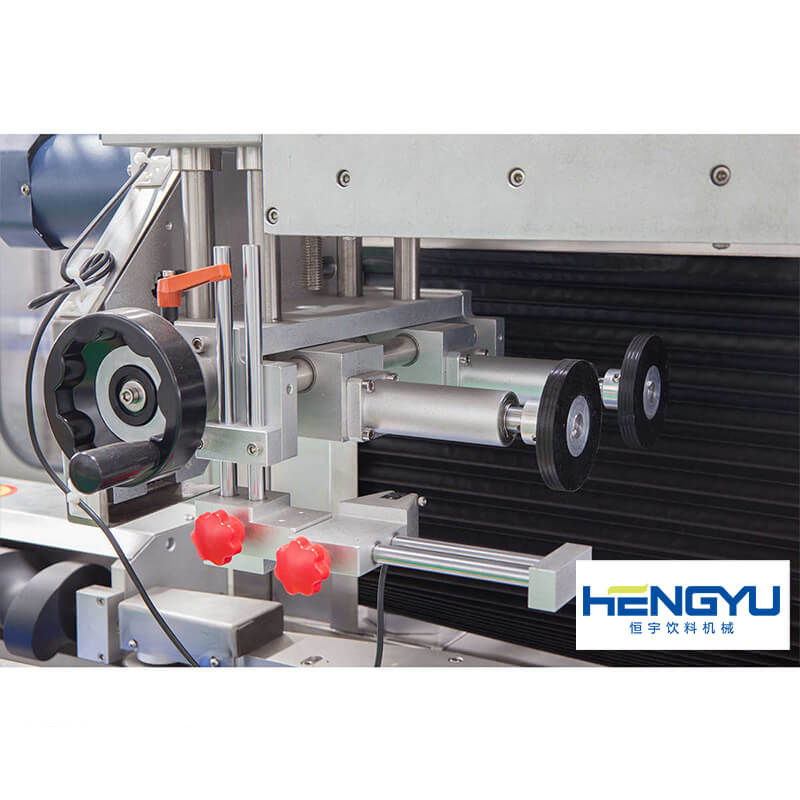

(1) Whole machine adopt qualified stainless

steel and good-quality of aluminum alloy , compact and reasonable

fracture,convenient to adjust;

(2) The label roll frame of shrinkage film with adjustable device, convenient

to adjust according to differ volume label 5″~10″paper tube.

(3) Simply installation, then can convenient for square and round bottle.

(4) No need of instrument, rotary mechanism is convenient to adjust, apply to

different bottle type.

(5) Unique sleeve labeling method, adopt pressing sleeve labeling method, not

only convenient but also reasonable.

(6) Control the feeding system automatically, and flat the shrinkage film and

adjust strain simultaneity.

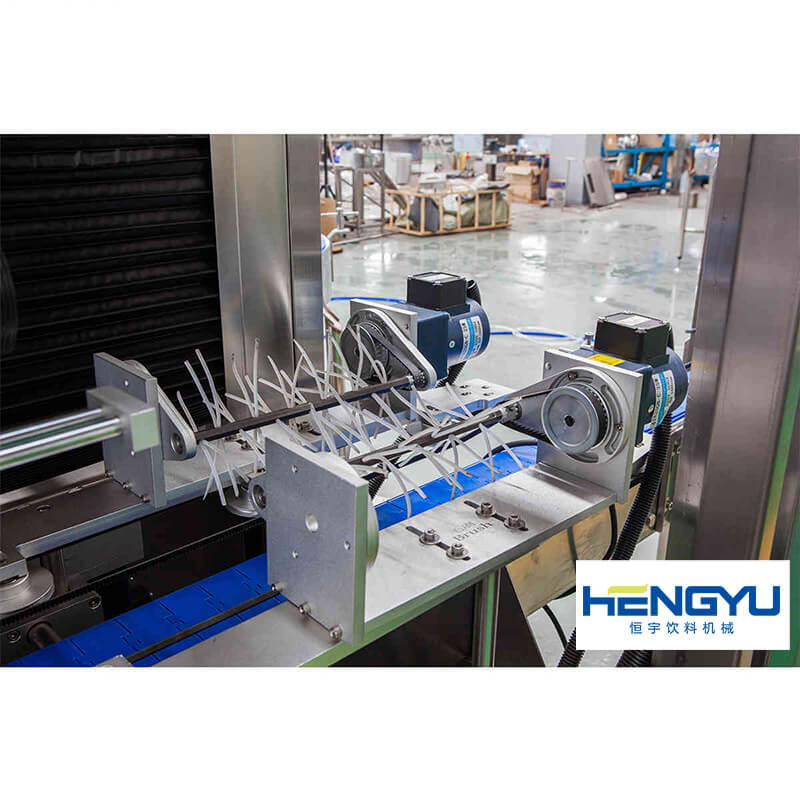

(7) Unique design knife plate, in the determined range, can change the knife

base. Knife changing quickly and conveniently.

(8) Middle guide-pole clip system, mould changing quickly, no need any

instrument.

(9) Label location system, can promote and demote in-phase adjust location

according to specific bottle type requirement.

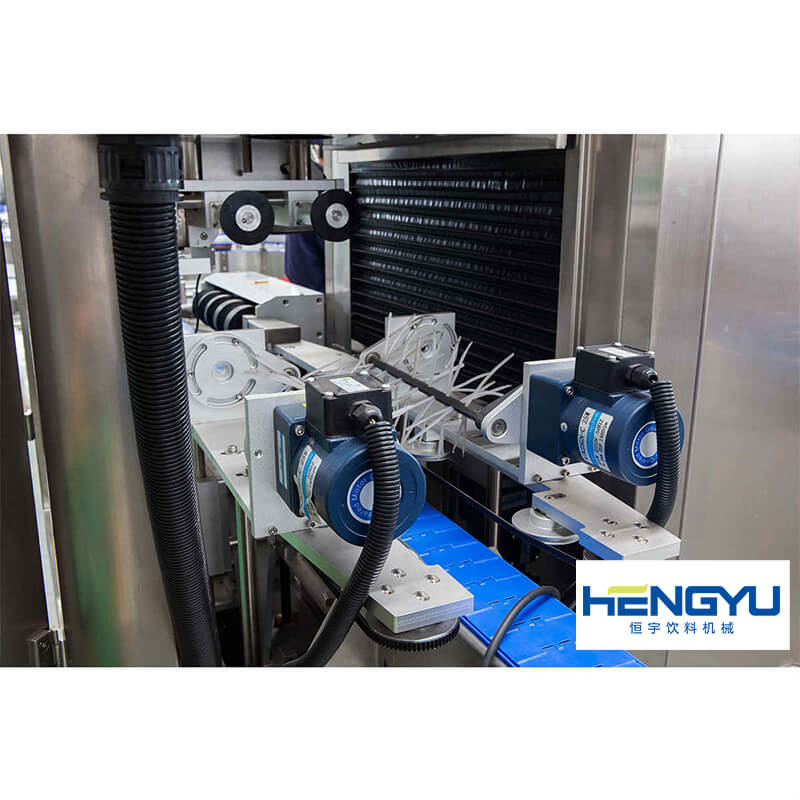

(10) Imported servo system and high-sensitivity photoelectric from Japan, with

high cutting precision of label.

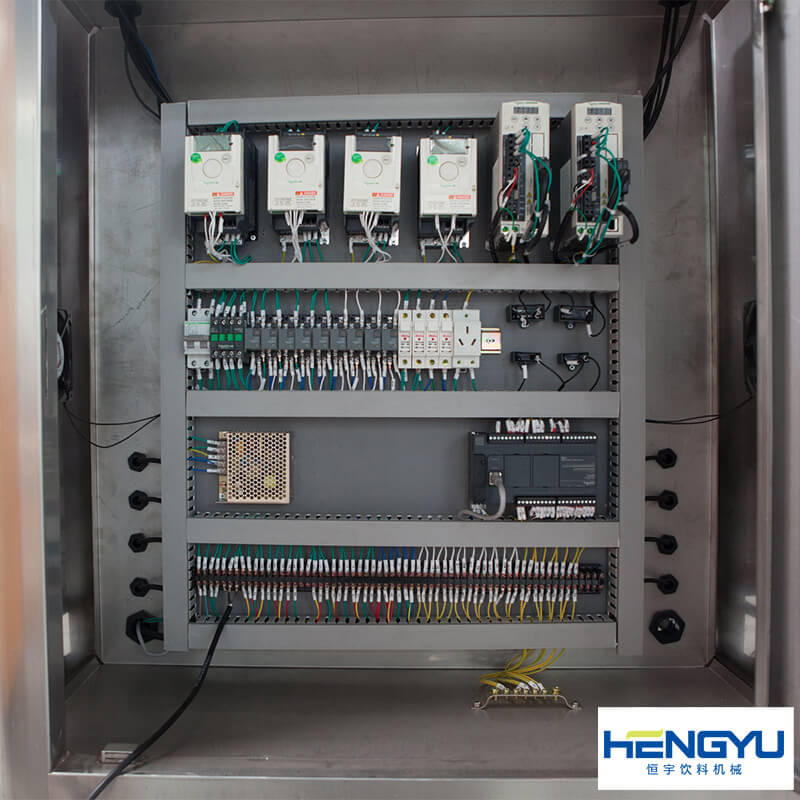

(11) Stainless steel electric control cabinet, OMRON PLC, imported from Japan.

(12) Adopt advanced man-computer Interface auto controlling technology, key

electric component all adopt international famous industrial brand.

Technical Parameter | ||

Model | HY-TBJ-150B | HY-TBJ-250B |

Capacity (on the base label length :500ml) | 3000BPH-6000BPH | 6000BPH-10000BPH |

Label size | Diameter 50-110mm | Diameter 30-125mm |

Bottle heights | Heights 50-200mm | |

Bottle diameter | Diameter 40-120mm | Diameter 28-125mm |

Label sleeve length | 40-150mm | 30-250mm |

Thickness | > 0.035mm | > 0.035mm |

Label material | PVC/ PET | PVC/ PET |

Electrical power | 2.5KW (380V 50HZ) | |

Overall diameter | 2440 * 890 * 2200mm | |

Weight | Approximate 750KG | Approximate 950KG |

Different Labels for Different Labeling Machine

(1) PVC / PET Shrink Film Label

Widely used in food, beverages, mineral

water and daily products.

Material: PVC

heat shrinkable film, PET heat shrinkable film.

PVC shrinkage:

longitudinal shrinkage 1%-4%, transverse shrinkage 55%;

PET shrinkage:

longitudinal shrinkage 1% -3%, transverse contraction 70%;

PVC/PET

heat-shrinkable labels printed flattened folding diameter: not more than 270mm;

Height:

according to customer requirements;

Thickness: 3

wire to 5.5 wire, according to customer requirements, roll or cut sheet can be;

Color: Up to 9

colors

(2) Sticker Label

Material: Coated paper, Synthetic paper,

BOPP.

Color: Up to 9

colors.

(3) OPP Label

Material: PVC heat shrinkable film PET heat

shrinkable film;

PVC shrinkage: longitudinal shrinkage 1%-4% lateral shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1%-3% lateral shrinkage 70%

Company Information:

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from Germany, Italy, the introduction of a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company has several series of independent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact modern office condition, has the specialized sales department, the research and development department, the technical department.

Packing & Delivery

Package

Type : As usual, we adopt wooden case as package type. It's suitable

for long-distance transport. According to customers' special demand, we

could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.

Packing details: |

Wrapping machine by protected film. |

Fixed with the base of wooden. That is enough strength for long time transport. |

Customers can choose delivery by ship, by air or by truck. Will choose favorable shipping partner. |

Our services

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging

machines. Engineer's roundtrip tickets, accommodation, and your side

travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.

1. Installation & adjustment

After the equipment are arrived at the customer's site, the customer is

responsible for unpacking and arranging the equipment according to the

placement drawing; and does under our install-adjust technicians'

guidance. Costs of the staff are decided at last.

2. Training

1). We are responsible for offering the technical training to user. The

training content includes the structure and maintenance of the

equipment, control and operation of the equipment. Through training,

users' technical staff can grasp and the skill of operation and

maintenance proficiently, and deal with the general troubles in time. We

will appoint qualified technical staff for the guidance.

2). The buyer can send staff to our company for learning.

3. Quality assurance

1). We guarantee the goods offered are brand-new, not used, with latest

design and suitable material made, and we guarantee the specification

of the equipment is consonance with the contract.

2). We guarantee

the line achieve product technical performance indicators within 5 days

after feeding operation through the correct guidance of the installation

and commissioning.

3). We are responsible for the fault and damage

of the production line caused by our design, technology, manufacture,

installation, adjustment and material defect etc. that all belong to our

responsibility.

4). The warranty period is 12 months after

acceptance check of the production line. If there is any different

between the furnished equipment in the customer's factory and the

equipment concerned in the contract, the users have the right to pass

the inspection book to the legal department to claim for compensation to

our company within goods warranty period.

4. Warranty

Offer 12

months maintenance period to the problem that caused by our design,

manufacture and the material quality, and offer the relevant parts and

effective service for free for above reason. We will offer a widely and

favorable technical support, after service all the time after guarantee

period.

FAQ

Q1: How to choose the most suitable machine and get the final suitable price?

A1: For beverage bottle Filling Machine, you need to reply us the following questions:

1. What kind of product (carbonated or no carbonated beverage, juice or water) for filling?

2. What's the volume of the bottle(Can)?

3. Could you show us picture of your Bottle/can?

4. Could you send some bottle samples to us?

5. What capacity do you need for production?

Q2: Do you have videos or manual for us to know the machine better?

A2: Yes, of course. Please email us and ask for it. We will send you soon.

Q3: How about your machine's quality?

A3: Every machine is applied with CE certificate, SGS certificate,

highly meets requirement of TUV, made of SUS 304 for food packaging;

SUS316 for pharmaceutical products packaging. Inspect certificate is

available.

Q4: What's the delivery time?

A4: Depending on

your order: for whole production line it is 40~60 workdays. bottle or

tube filling machine, labeling machine, capping machine, unscrambling

machine, can sealing machine will be 30~40 days. Other simple equipment

will be around 20 days. The above delivery time is calculated after

receiving the down payment as well as sample bottles / tubes and

materials.

Q5: Is there MOQ for your machine?

A5: 1 set is acceptable. Of course, if you order more, it will be fine and its price will be more competitive.

Q6: How to install the machine?

A6: Please do not worry. We will send you detailed video and

instruction manual for your reference. Customer also can appoint your

engineers to our factory to learn. Our engineers also can go abroad to

install the machine well, however, customer needs to pay round air

tickets, hotel and service expenses.