© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

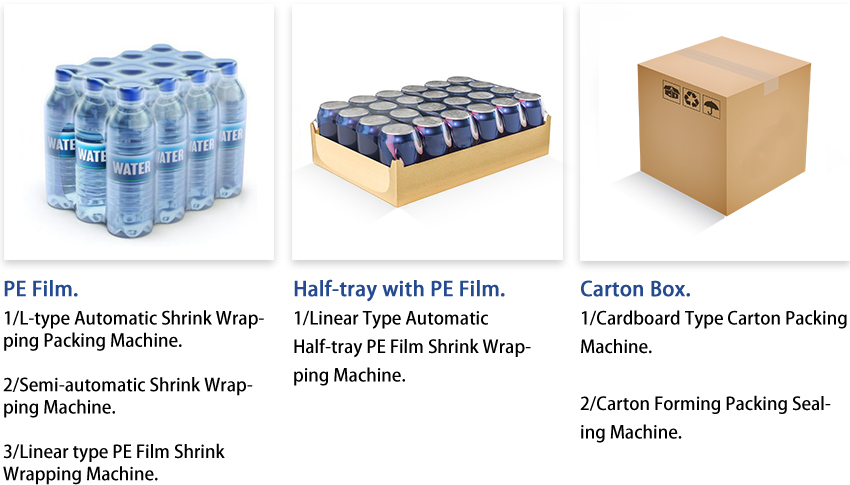

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale, so it needs to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes.

Specifications: Full automatic thermo shrink film packaging machine Packing speed is around 6000bph to 30000bph Wrapping quality: reliable Product Description: This straight line high speed automatic shrink wrapping package machine is suitable for beverage ,water and beer industry. The packing speed is around 12000bph to 3000bph .It is a high speed PE film shrink package machine, it is composed by bottle separate bottle , sealing device, and shrink tunnel and extend structure and etc. Frequency control ,secondary bottle transport device.

|

Features

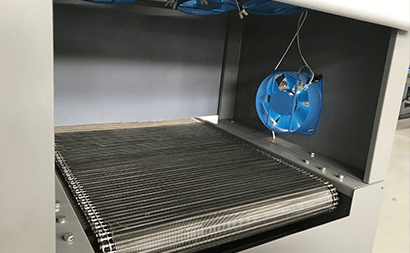

1. It has full-auto characteristics , such as conveying materials ,ordering bottles ,wrapping film ,shrinking ,cooling and shaping and others.

2. It adopts advanced film thermal sealing technology. The seal seam is clear. It is firmer and more beautiful

3. Conveying film adopts induced induced switch control, adjust the conveying film length reliably and reduce consumption.

4. The conveying motor adopts imported frequency converter control. Its conveying is smooth and the stepless govern is carried out

5. It adopts advanced screw air supplying circulating structure and 3-layer insulating treatment.The wrapping is film and save energy.

Technical parameters

Specification of Horizontal wrap machine: | |

Voltage | 220V 50HZ |

Power | 2KW |

Max. packing size(L W H): | 420 280 350mm |

Package speed | 17-25bags/min |

Air source pressure | 0.5-0.7Mpa |

Equipped with infrared ray hot air circle shrink tunnel | |

Power | 22KW |

Conveyor speed | 0-15m/min |

Shrink tunnel size | 2465 840 1700mm L W H |

Note: the machines packing size and shrink tunnel is designed according customer requested speed and bottle size | |

Dimension For The Whole Unit | L5500mm×W3200mm×H2100mm |

Thermal Shrinkage Passage Dimension | L1800mm×W650mm×H450mm |

Max Package Dimension | L600mm×W400mm×H350mm |

Packaging Speed | 8-10Pcs/minute |

Transfer Belt High | 800-1200mm |

Sealing And Cutting Time/Temperature | about 0.5-1.5s 140oC-160oC |

Operating Power Supply/Power | three-phase-five-line 380V 20KW |

Operating Air Pressure | 0.6-0.8Mpa |

Companies have many years of research results and production experience as the basis, widely absorb and digest the advantages

of the same industry at home and abroad and one after another from Germany ,Italy ,the introduction of a full set of the latest

beverage packaging machinery technology. To provide high quality beverage equipment for domestic and international customer.

The company has several series of independent research and development products ,has obtained the national patent.

As the senior beverage machine manufacturer ,the working environments is elegant ,has the perfect modern office condition,

has the specialized sales department ,the research and development department ,the technical department.

Q1: How to choose the most suitable machine and get the final suitable price?

A1: For beverage bottle Filling Machine, you need to reply us the following questions:

1. What kind of product (carbonated or no carbonated beverage, juice or water) for filling?

2. What's the volume of the bottle(Can)?

3. Could you show us picture of your Bottle/can?

4. Could you send some bottle samples to us?

5. What capacity do you need for production?

Q2: Do you have videos or manual for us to know the machine better?

A2: Yes, of course. Please email us and ask for it. We will send you soon.

Q3: How about your machine's quality?

A3: Every machine is applied with CE certificate, SGS certificate, highly meets requirement of TUV, made of SUS 304 for food packaging; SUS316 for pharmaceutical products packaging. Inspect certificate is available.

Q4: What's the delivery time?

A4: Depending on your order: for whole production line it is 40~60 workdays. bottle or tube filling machine, labeling machine, capping machine, unscrambling machine, cansealing machine will be 30~40 days. Other simple equipment will be around 20 days. The above delivery time is calculated after receiving the down payment as well as sample bottles / tubes and materials.

Q5: Is there MOQ for your machine?

A5: 1 set is acceptable. Of course, if you order more, it will be fine and its price will be more competitive.

Q6: How to install the machine?

A6: Please do not worry. We will send you detailed video and instruction manual for your reference. Customer also can appoint your engineers to our factory to learn. Our engineers also can go abroad to install the machine well, however, customer needs to pay round air tickets, hotel and service expenses.